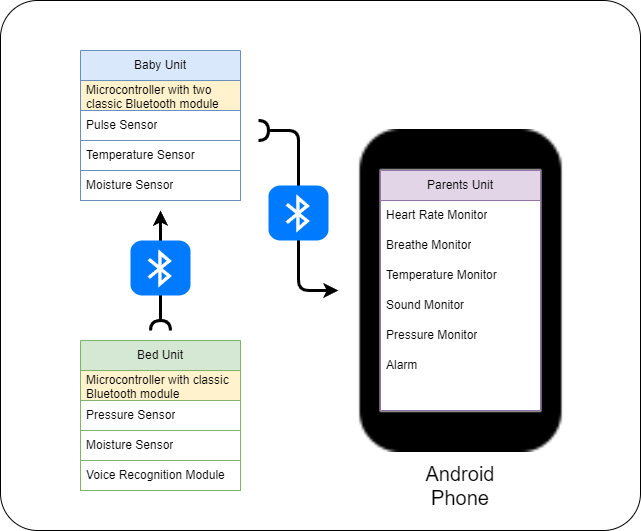

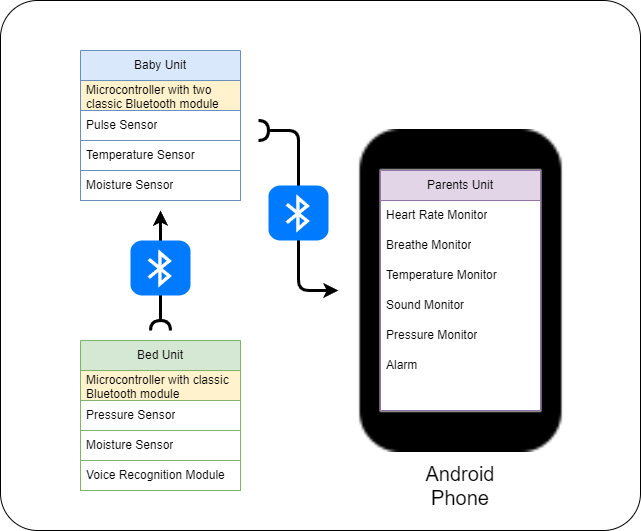

Baby Monitoring System for Sleep Apnea Detection

A baby monitoring system to detect sleep apnea in babies.

The system consists of three units: A android phone[Parent Unit], A bed unit and a baby unit.

The Baby unit is attached with the baby with a special outfit.

The Baby unit monitors baby's Heart Rate, Breathing pattern and Urination pattern.

The Bed unit monitors baby's presence on the bed, Urination pattern and Crying pattern.

The Parent Unit monitors data received from the bed unit and baby unit, and make decisions and alarm parants accordingly.

The data transmission of the whole system uses bluetooth system.

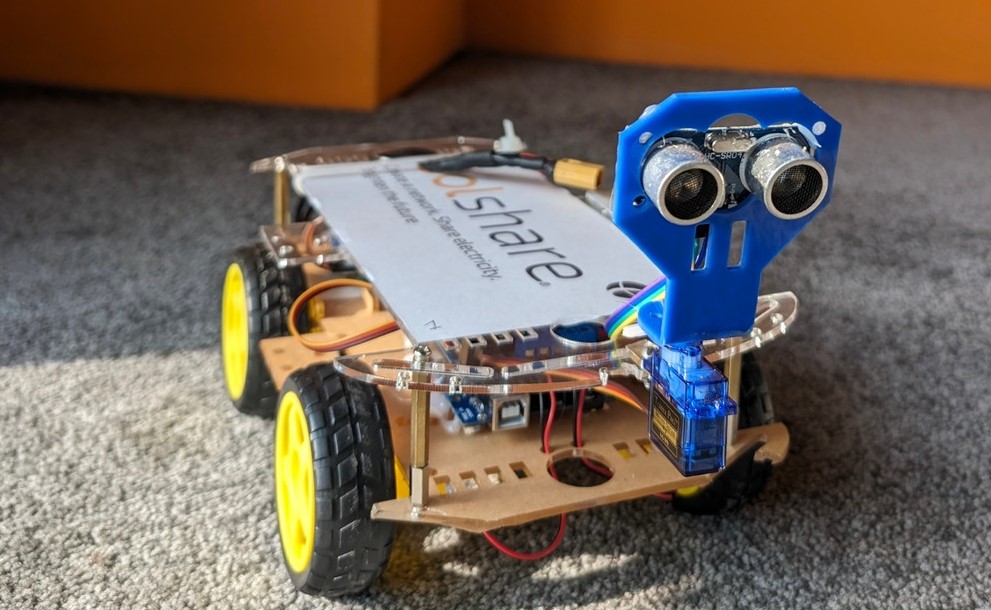

A Self Balancing Car

The self-balancing car employs sophisticated technology to maintain stability while in motion.

Its core components include an Inertial Measurement Unit (IMU) consisting of accelerometers and gyroscopes, a microcontroller and motorized wheels.

The IMU continuously measures the vehicle's roll axis and movement, sending this data to the processor.

A control algorithm then interprets the information and adjusts the motorized wheels to counteract any tilting, creating a closed-loop feedback system.

This dynamic process allows the self-balancing car to respond in real-time to changes in its orientation, ensuring a smooth and balanced ride.

View More

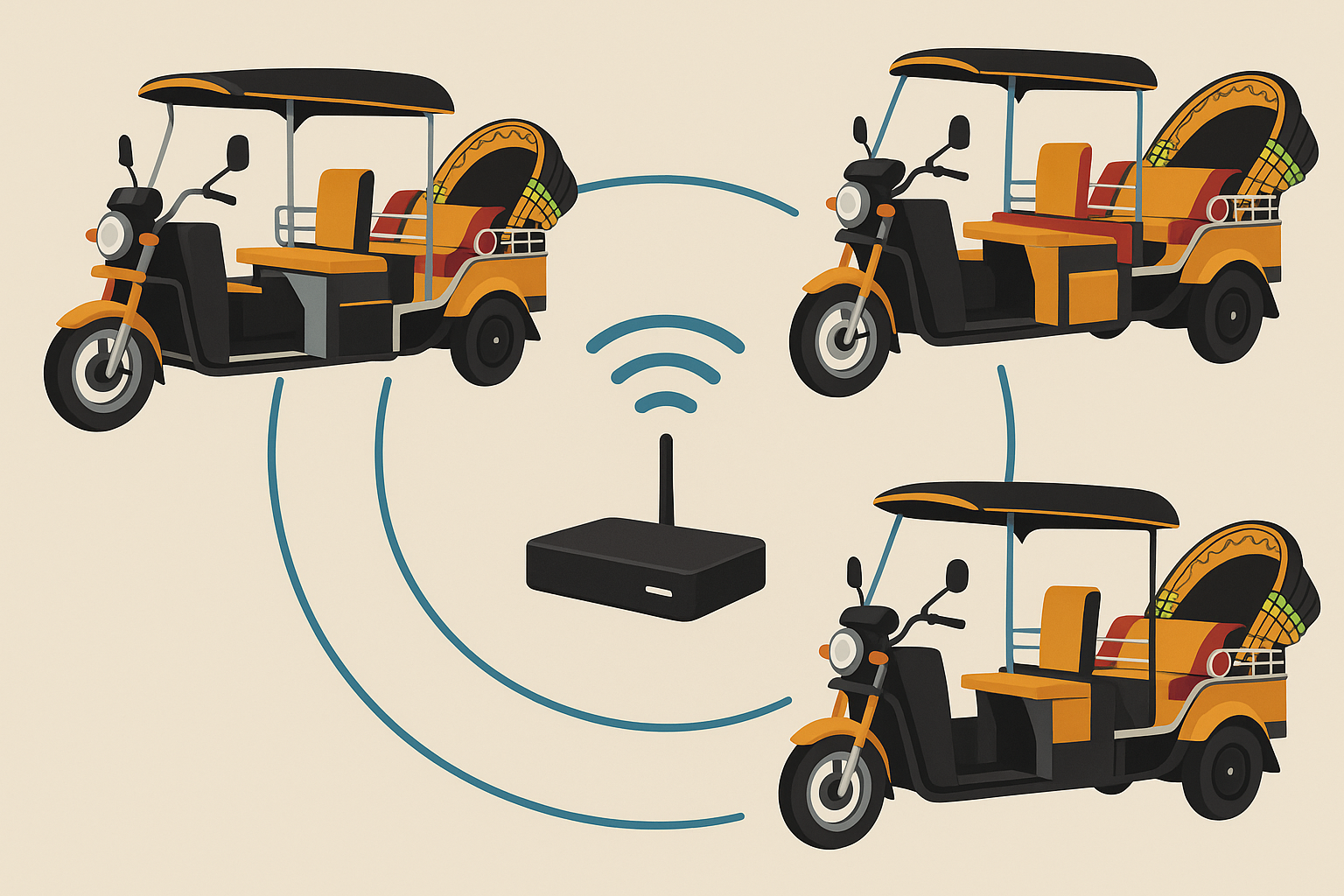

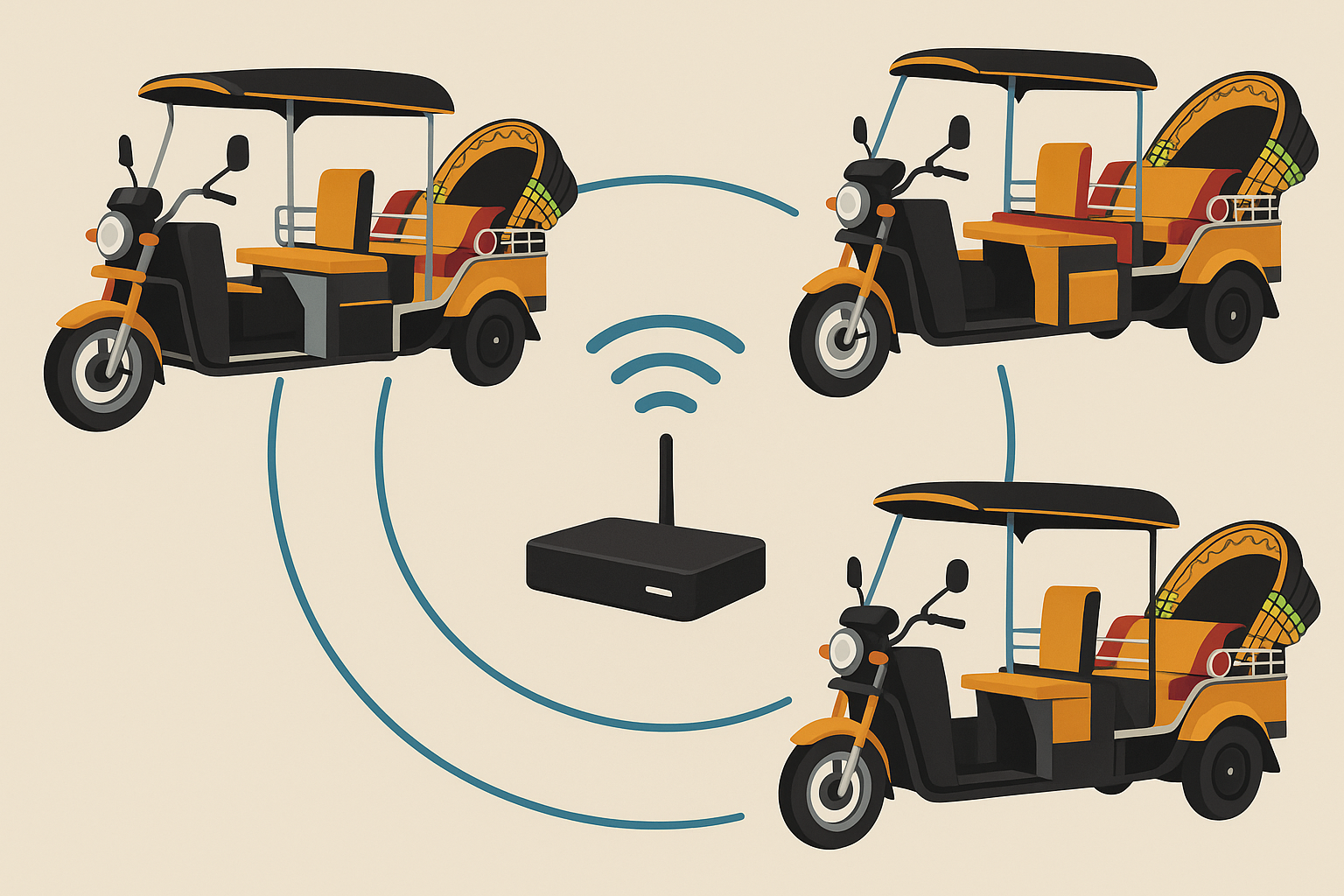

Wireless Edge-Controlled Vehicle-to-Grid Solution

A smart energy management system was designed to transform a fleet of electric

tuk-tuks into a Virtual Power Plant (VPP). A stationary edge device was installed

at the garage, where each returning tuk-tuk is automatically connected, its battery

status is collected, and its eligibility for vehicle-to-grid (V2G) operation is determined.

During peak demand hours, power is fed back to the grid by eligible tuk-tuks,

reducing load pressure and improving overall energy efficiency. Through this project,

experience was gained in edge computing, wireless device orchestration, IoT automation,

and intelligent energy systems for real-world mobility fleets.

Read More

Hydroponics System

An automated hydroponics system involves integrating various components such as reservoir, pumps and

sensors to create a self-sufficient and efficient plant cultivation setup.

The reservoir contains a precisely formulated nutrient solution.

The solution is then circulated through a delivery system, such as a drip system, ensuring even distribution to the plant roots.

The pH and EC levels of the nutrient solution is continuously monitored using sensors to monitor and maintain optimal pH and EC levels in the nutrient solution.

A microcontroller monitors the pH and EC levels and surrounding temperature, to automate the nutrient pump and nutrient delivery.

This automated hydroponics system not only streamlines the cultivation process but also provides precise control over growing conditions,

resulting in accelerated plant growth and increased yield.

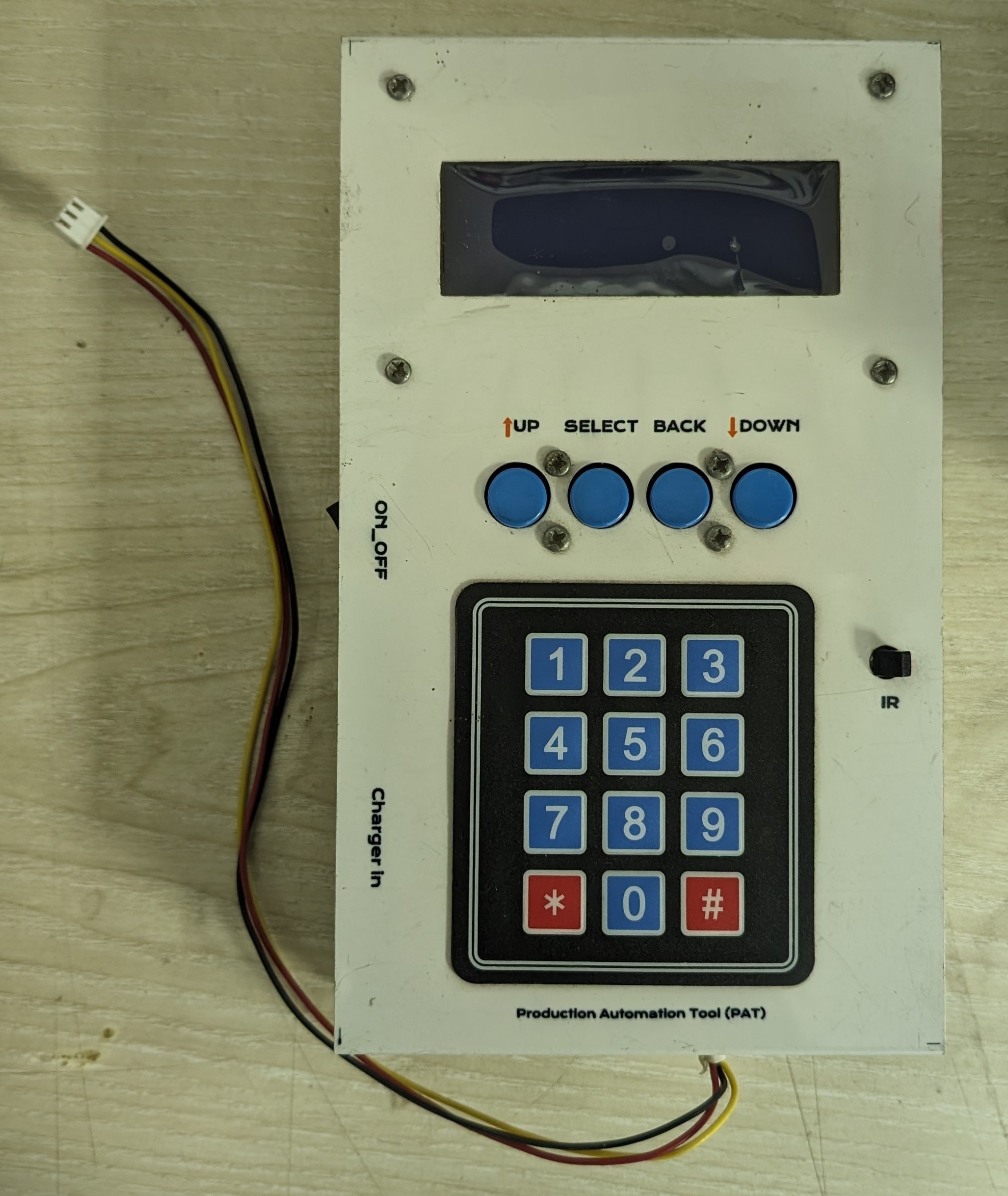

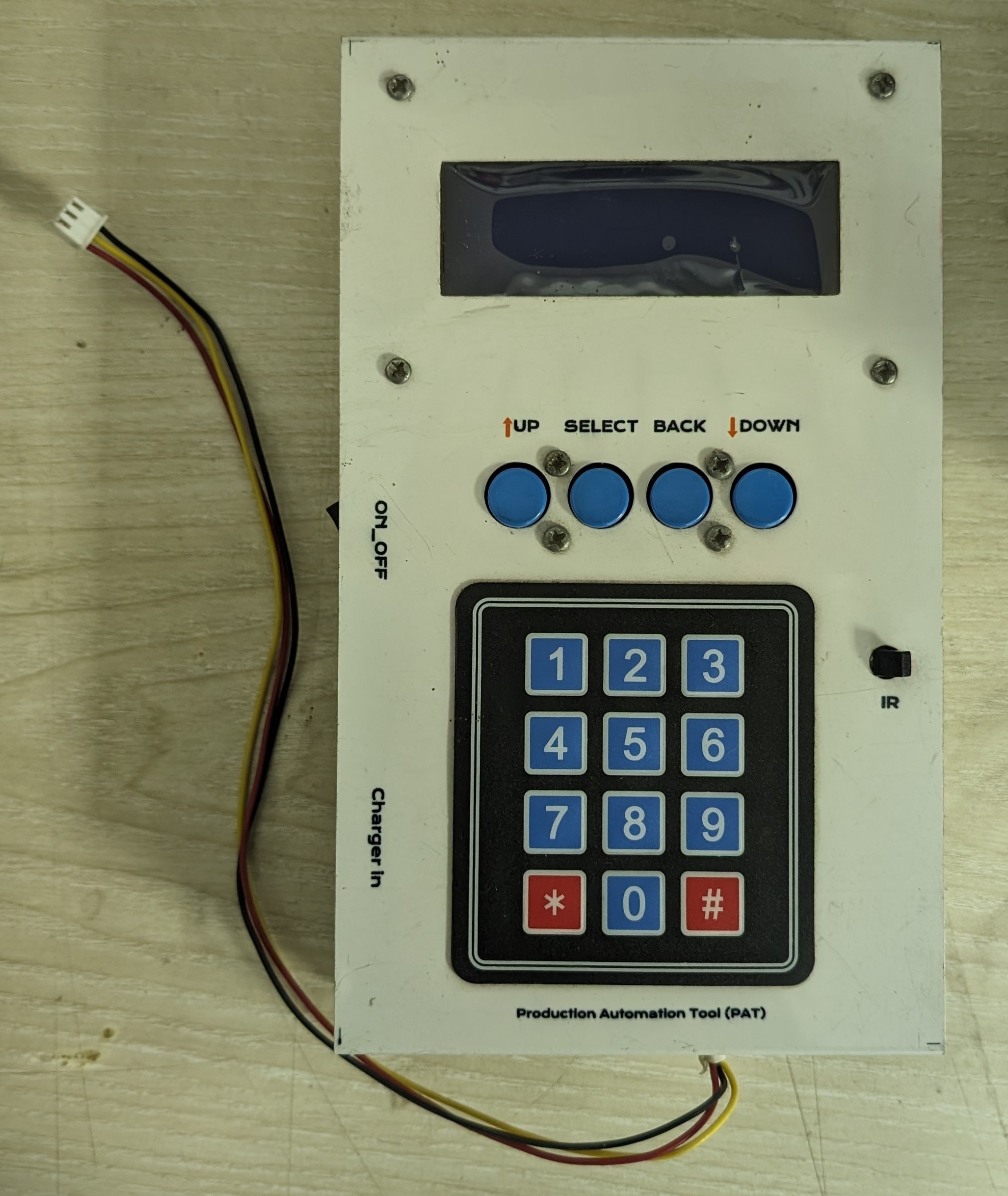

Human Machine Interaction(HMI) device

The HMI device is used to configure another device.

User sets different parameters using the navigation buttons, a keypad and a LCD display.

The communication with the other device is done using Infrared(IR) signal.

The system is powered by a rechargeable Li-ion battery pack.

Quadcopter for rescue operations

The Clean Flight software was modified to properly interface the components

with the quad copter. The video feed from the FPV (First Person View) camera

was sent using a video transmitter to a laptop. The laptop was used to decode

the QR code captured by the FPV camera. According to the decoded value of the

QR code, the Quadcopter had to perform task accordingly. Additionaly, there was

a storage with a hatch on the under side of the Quadcopter. The hatch mechanism

was operated by the UAV pilot manually.

Use cases of this drone:

1. Identify and provide emergency and urgent health care.

2. For surveillance by the law and order forces.

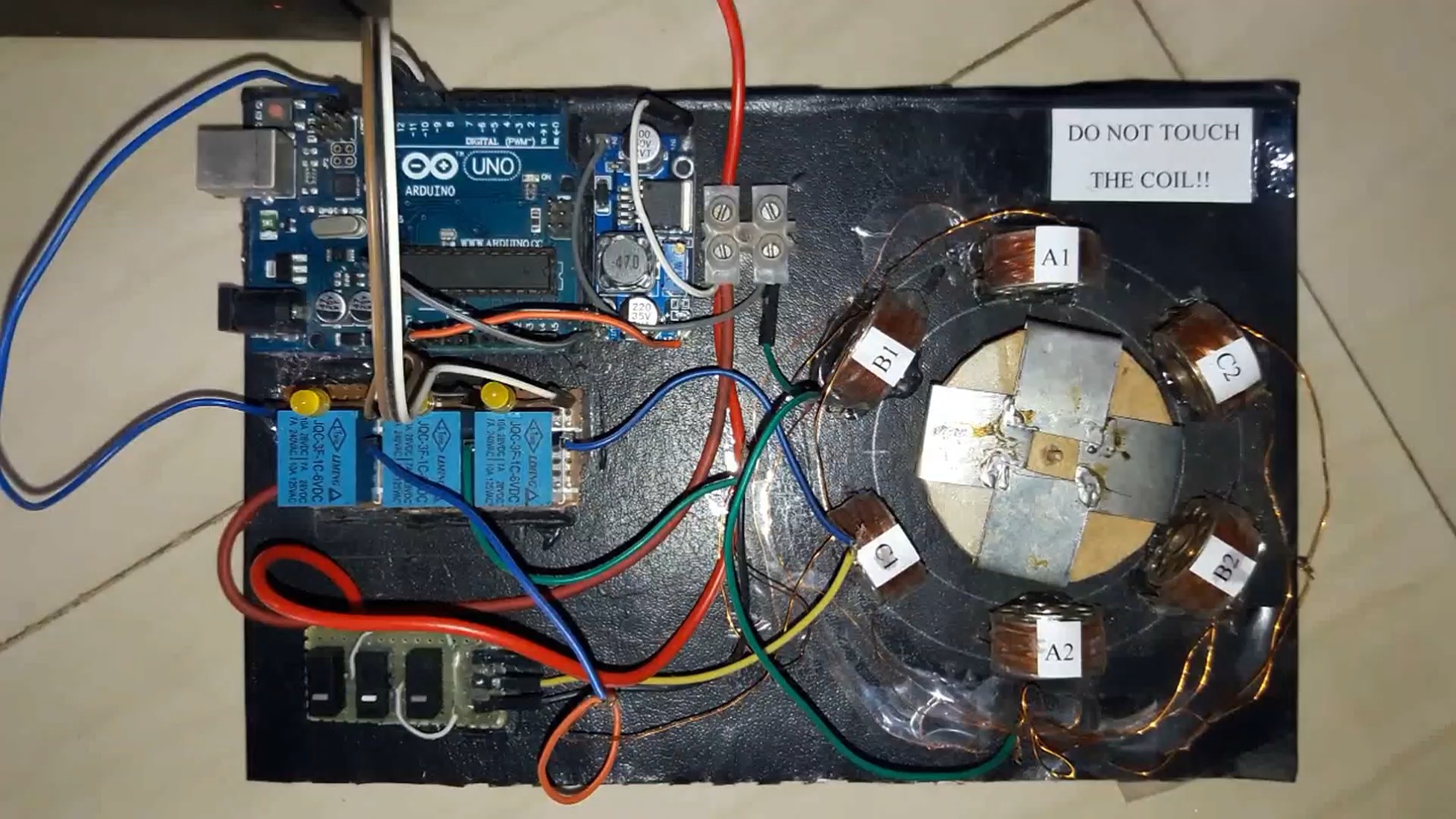

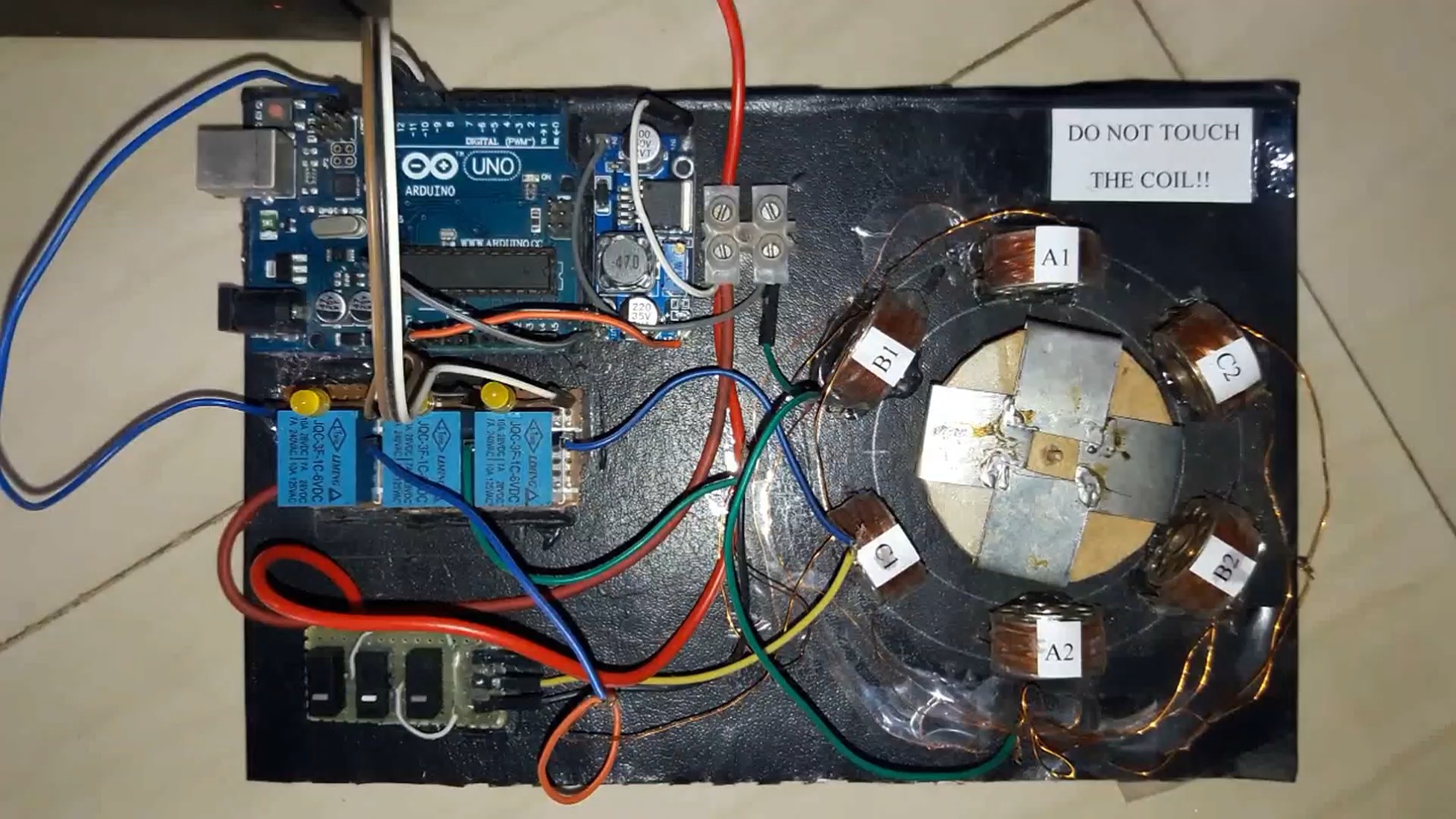

DC motor model

A DC motor model was created to display the operating

principles of a DC motor. Six stator coils were used in this model and a thin

metal plate was placed in the middle as the rotor. To power the motor, a DC

12V power supply was used.

This motor model had both manual and automatic operation.

The manual operation was done by user by pressing the Tactile Switches. Each

Switches energized two opposite stator coils at the same time and attracted the

rotor in that direction.

As for the automatic operation, relays are being used instead of the tactile switches.

The relays are controlled by a microcontroller[Arduino328p].

Rest of the operation is similar to the manual operation.

View More